Forging

The process of forging steel at Northland Forge Ltd. begins by cutting steel bars, which are produced at quality North American Steel Mills.

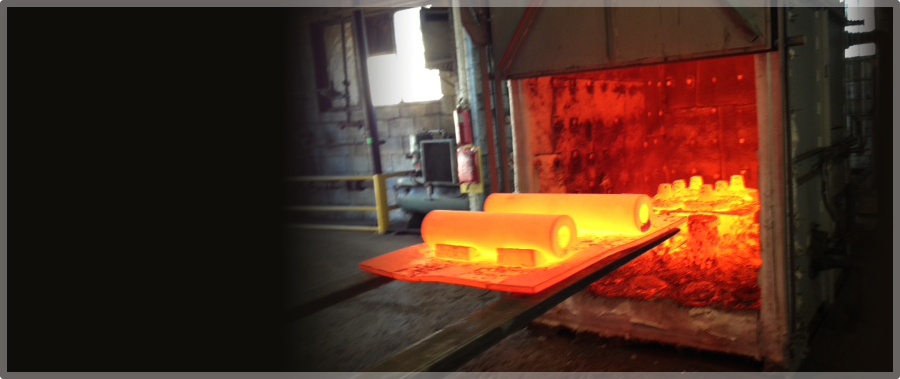

- The cut pieces are pushed through our temperature controlled forging furnace and heated to the proper forging temperature.

- The hot blanks are removed from the furnace and forged into the desired shape using one of our forging hammers and the proper die set.

- Once the part has been forged, we trim off the excess steel on a trimming press.

- The part is Hot Stamped with a unique "Heat Code" to maintain traceability.

- The part is then taken away to cool.

|

|

|

Northland Forge Ltd.

6620 -100 Street

Edmonton, AB T6E 3X5

Phone: 780-414-0613

Fax: 780-439-1131

Email: nforge@telus.net

Key Personnel:

Ken Attwood, President

Forging Equipment:

- Beche DGH 13 Forging Hammer c/w Trimming Press

- Beche DGH 6 Forging Hammer c/w Trimming Press

- Cold Cut and Band Saws for Material Preparation

Call Now

Feel free to give us a call for information about our forgings